Helicoil |

|

|

|

| |

The HeliCoil product portfolio includes - Genuine HeliCoil Product Range available as HeliCoil Wire Thread Inserts - Free Running Inserts & Screw Locking Inserts, HeliCoil inserts of Nimonic 90, Nitronic 60, Titanium alloys, Inconel X-750, Phosphorus Bronze, and various other Space Age Metals, in addition to the standard range of HeliCoil available in 18-8 Grades of Stainless Steel such as SS-304, SS-316 and DTD 734. Also available are variety of Thread Repair Kits - HeliCoil Professional Kits, HeliCoil Master Kits, HeliCoil After Market Kits, HeliCoil Insertion Tools, HeliCoil Thread Taps, HeliCoil Thread Plug Gauges, HeliCoil Extraction Tools, HeliCoil Manual Tang Break off Tools, HeliCoil Automatic Spring Loaded Tang Break off Tools and Semi-Automatic & Automatic equipment for HeliCoil installation.

|

| Genuine HeliCoil products |

Helicoil Thread Repair Kit - Professional |

|

|

|

| |

Helicoil Thread Repair Kit - Master |

|

|

|

| |

Helicoil Thread Repair Kit - After Market |

|

|

|

| |

Helicoil Free Running Inserts |

|

|

|

HeliCoil standard range is available in Stainless Steel AISI-304/ DTD734, metric series ranges from M1.6, M2 to M56 & in unified series from UNC / UNF 1-64 to 1-1/2 inch. HeliCoil is also available in strip feed or reel mounted form, HeliCoil in strip feed form are best suited for significantly reducing the installation time using power tool for installation of inserts.

HeliCoil Inserts or Wire Thread Inserts are made of cold rolled 18-8 grade Stainless Steel to AS7245 , MIL-I-8846 & DTD734 specifications. This wire is cold rolled to a diamond cross section producing an ultimate tensile strength of approximately 1375-1725 MPa, mirror like surface finish of 2-4 Microns and flank hardness of RC 43-50 which is far in excess of the usual tapped materials and best suited for most of the industrial needs. HeliCoil Inserts can also be supplied in other materials such as SS-316, Inconel X-750, Titanium Alloys, Nimonic 90, Nitronic 60, Phosphorus Bronze, Beryllium Copper and with special coating and plating requirements such as Cadmium plating, Silver plating, Zinc plating, Nickel plating and dry film lubricants, Anti- Corrosion/ Salt spray resistant coatings.

|

|

|

|

|

| |

Helicoil Screw Locking / Self Locking Inserts |

|

|

|

HeliCoil Screw Locking Insert as standard is available in Stainless Steel AISI-304/ DTD 734 . Metric series ranges from M2 to M39 & unified series from UNC / UNF 1-64 to 1-1/2 inch. HeliCoil Screw Lock Insert is also available in strip feed or reel mounted form .

HeliCoil Locking Insert provides an exclusive, resilient internal locking thread that grips the bolt and prevents it from loosening under vibration or impact. One or more coils of the HeliCoil insert, having a series of straight segments/ chords, achieve locking action. HeliCoil Locking Insert permits repeated assembly and disassembly and will not relax their grip on the screw even in tough metals such as cast iron, alloy steel, titanium, etc. HeliCoil Locking Insert positively secures threaded members against loosening caused by vibration and shock. HeliCoil Locking Insert has a high reusable factor permitting frequent removal and reassembly of bolt without appreciable loss of torque. It has positive self-locking torque, complying with NASM8846, MA1565 and MIL-N-25027. It eliminates the usage of lock wiring, lock nuts, lock washers, chemical compounds, plastic pellets/ patches and other locking mechanisms. The HeliCoil Locking Inserts are subjected to extensive tests in tension, torque, shear, vibration and fatigue, conducted by the American & European companies. Its applications include sectors like Aviation & Aerospace, Electronics, Industrial, Automotive and Military.

|

|

|

|

|

| |

Helicoil Tangless Inserts |

|

|

|

| |

Helicoil Military and Aerospace Standard Parts |

|

|

|

Heli-Coil inserts and tooling comply with the following standards and Specifications:

• MS122076 ; NASM122076 thru MS122275 ; NASM122275. Insert, corrosion resistant Helical Coil Coarse Thread (Inch Series)

• MS124651 ; NASM124651 thru MS124850 ; NASM124850. Insert, corrosion resistant Helical Coil Fine Thread (Inch Series)

• MS21209, NASM21209. Insert Screw Thread – Self Locking (Inch Series)

• MS33537, NASM33537. Insert – Standard Dimensions, Assembly

• NASM8846. Insert, Screw Thread, Helical Coil

• MA1565. Insert, Screw Thread,Helical Coil (Metric Series)

• MA1567. Insert, Screw Thread, Helical Coil (Metric Series), Standard Dimensions,Assembly

• MA3279, 3280, 3281. Insert, Screw Thread, Helical Coil (Metric Series), Screw-Locking

• A-A-59158. Tools for inserting and extracting Helical Coil Inserts

• FED-STD-H28. Screw Thread Standards for Federal/Services

• AS3094 thru 3097/AS3080 thru 3083 Special Locking Torque Inserts

Other special standards & parts such as:

-

AGS3600, AGS3700, AGS4677, AS6733, AS6734, AS8455, AS8456, AS3094 – AS3097

,

BACi12AE, DHS1673, DHS1674, DSR1002, DSR1003, DSR2786, DSR3359

LN9039, LN9039A, LN9499, LN9499A, NAS1130, NSN5340, P312201, P312219

GE part series N926AP, N926BP, N926SP, N926CP, N926

|

|

|

|

|

| |

Helicoil Insertion Tools |

|

|

|

| |

Helicoil Thread Cutting Taps |

|

|

|

| |

Helicoil Thread Plug Gauges |

|

|

|

| |

Helicoil Tang Break-Off & Extraction Tools |

|

|

|

The driving tangs of HeliCoil Inserts should be removed to eliminate their interference with the end of the assembled bolt. Their removal provides greater latitude in the depth location of the bolt. Manual Tang Break-Off Tools are available for use with inserts up through 18mm / 3/4" nominal diameter. Auto /Spring Loaded Tang Break-Off Tools are available for use with inserts up through 12mm / 1/2" nominal diameter. The operation of Auto Tang Break-Off Tools is automatic, having a spring loaded, easily triggered punch that strikes a sharp, uniform blow against the tang of the installed insert. It can be operated with one hand. For larger sizes use long nosed pliers. Bend tang up and down to snap off at notch. Tools to remove HeliCoil Inserts are available for ranges M1.6, M2 – M2.2, 2.5 - 4.5mm, 3 - 8,. 5 - 10mm, 10 - 3/8", 11 - 24mm, 7/16" - 1", 27 - 39mm, 1-1/8" - 1-1/2". Extraction is done by applying the tool to the insert, striking the head of the tool a light blow and turning it counterclockwise, maintaining steady downward pressure.

|

|

|

|

|

|

|

| |

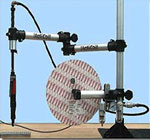

Re-Designed Heli-Coil® Power Tool Holder |

|

|

|

The re-designed Heli-Coil power tool holder utilizes a strong tubular design to decrease weight and increase rigidity and tool support. The new unit now features a solid base that can be bolted to the work surface to maintain perpendicularity between the tool and the work piece. Because of this, the tool holder is especially recommended for use with small thread sizes (#2-56, M2.2, M2.5) and is ideal for use in applications with inserts to be installed within the same plane.

Additional features include a filter-regulator-lubricator mount and insert reel mounting arm. The tool can be quickly and easily converted for use with either the traditional air operated installation tool or the Heli-Coil Electronic Installation System.

|

| |

Features & Benefits

-

• Provides precise, vertical positioning of the Heli-Coil Power Installation Tool

-

• Adjusts easily without tools

-

• Arm can be locked in place for permanent positioning

-

• Includes arm for Heli-Coil Strip-Feed Insert reels

-

• Up to 27" Reach

-

• Lightweight

-

• Portable

-

• Base designed for optional permanent mounting

-

• Order Part Number 13537

|

|

|

| |

The New Heli-Coil® "One Step Automation" Tool |

|

|

|

|

| |

|

| Download Product Catalogues |

|

|

| |

|

|

| |

|