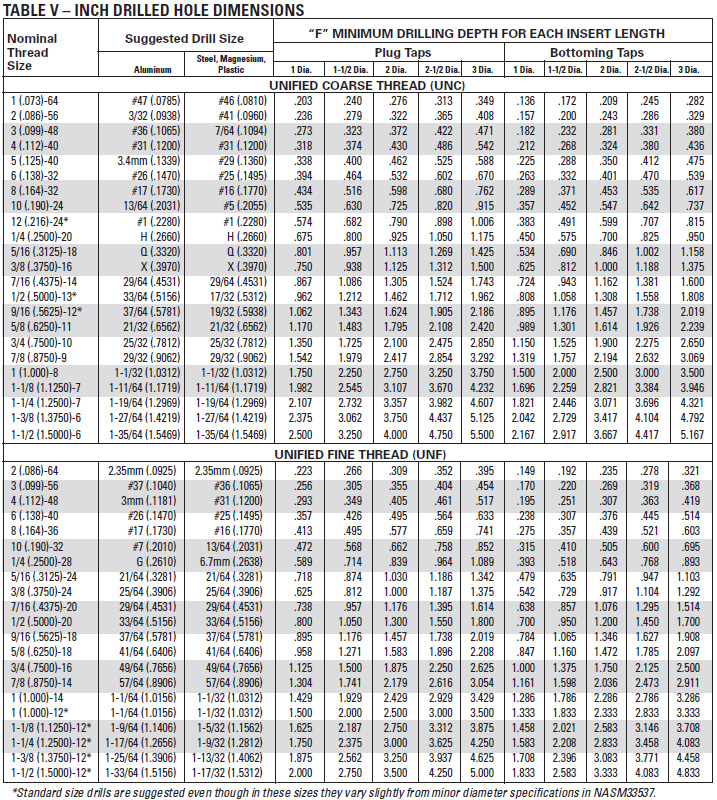

| Helicoil Drill Chart |

|

|

|

| The minimum drilling depths shown

below allow for the following

recommended practices: |

- Countersinking the drilled hole

to prevent a feather edge at the

start of the tapped hole.

- 3/4 - 1-1/2 pitch of insert "set down" to allow for

maximum production tolerance.

Dimensions are shown for both

plug and bottoming taps.

|

|

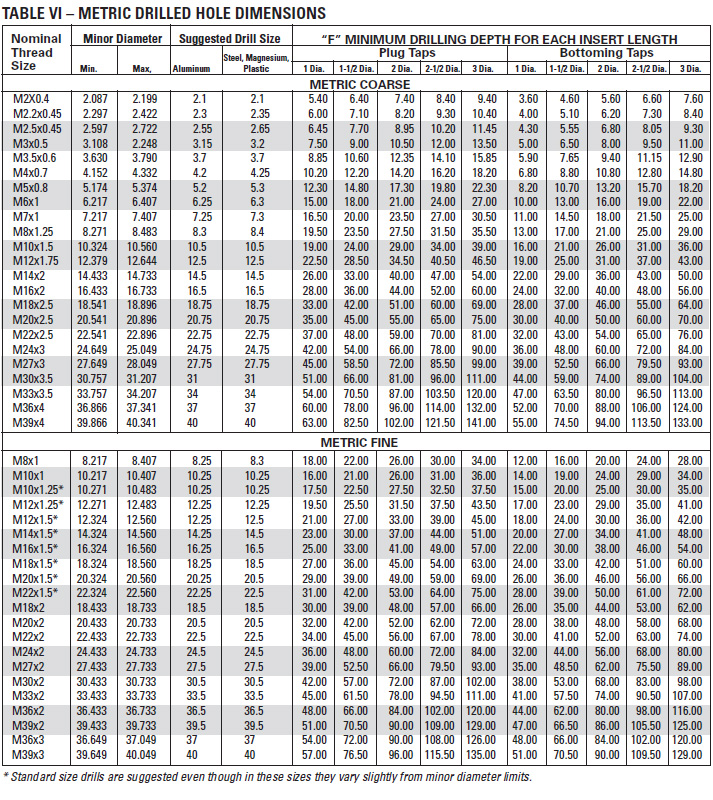

| Helicoil Drilling Data - Metric |

|

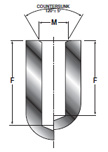

For plug Taps 5/16" or M8 and smaller. F is equal to the insert

nominal length (Q) + ½ the nominal

bolt diameter + 5 Pitch (allowing

for tap chamfer, countersink and

maximum “set-down”).

For Plug Taps 3/8" or M10 and larger F is equal to the insert nominal

length (Q) + 5 Pitch (allowing for tap

chamfer, counter sink and maximum

“set-down”).

For bottoming Taps. F is equal to

the insert nominal length (Q) + 3

Pitch (allowing for tap chamfer,

countersink and maximum

“set-down”). |

|

|

|

| helicoil, helicoil insert, helicoil inserts, heli-coil, helicoil tap, helicoil insertion tool, helicoil removal tool, helicoil thread chart, helicoil drill chart, helicoil thread gauge, helicoil kit, helicoil tool kit, helicoil thread repair kit, NASM21209,MS21209 ,NASM33537,MS33537 ,MS122076 to MS124831,NAS1130, LN9039,LN9039A, LN9499 ,LN9499A,DIN8140, MS122076 to MS124831,MA3279 ,MA3280 ,MA3281 ,MA3329 ,MA3330 ,MA3331, SAE8879, BACi12AE,AGS3600, AGS3700, AGS4677, AS6733, AS6734 , AS8455 ,AS8456 ,AS3094 AS3095,AS3096, AS3097, GE N926, N926A ,N926B ,N926C, helicoil tool holder,helicoil tool set ,wire thread insert, self locking insert, screw locking insert |

|

| Download Product Catalogues |

|

|

| |

|

|

| |

|