| Helicoil Tapping Chart |

|

|

|

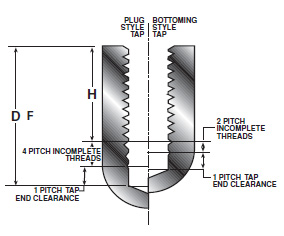

The minimum tapping depths

shown below (Dimension H) are the MINIMUM for countersunk holes and insert set-down of 1-1/2

pitch maximum. The calculation for

Dimension “H” is:

H is equal to insert nominal length +1 Pitch.

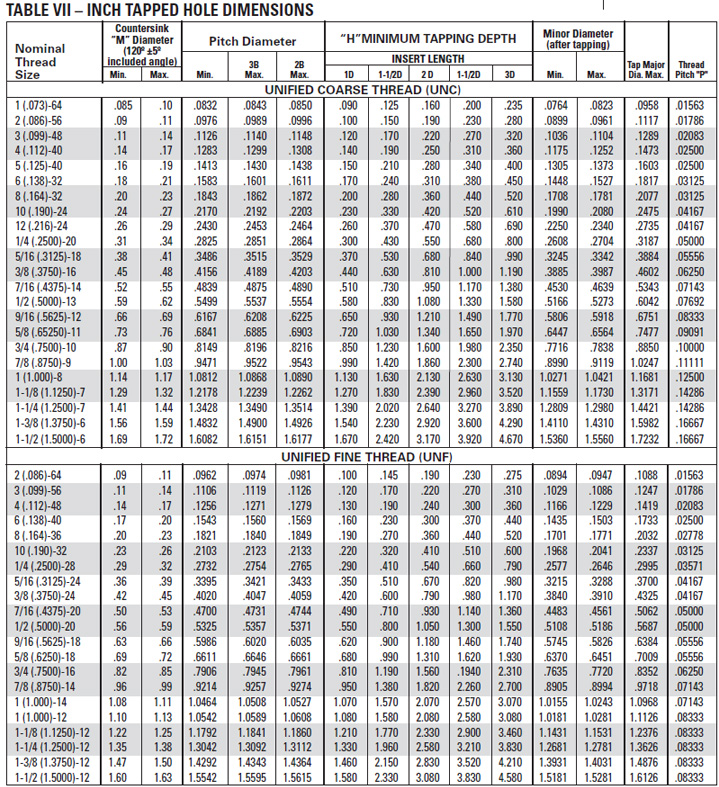

The tapped hole must be held within

the stated pitch diameter limits

for the required class of fit for the

installed Heli-Coil insert.

When anodize, Iridite or other

finishes are used, all tapped hole

dimensions must be met after the

finishes are applied. |

|

|

|

| Helicoil Tapping Data - Metric |

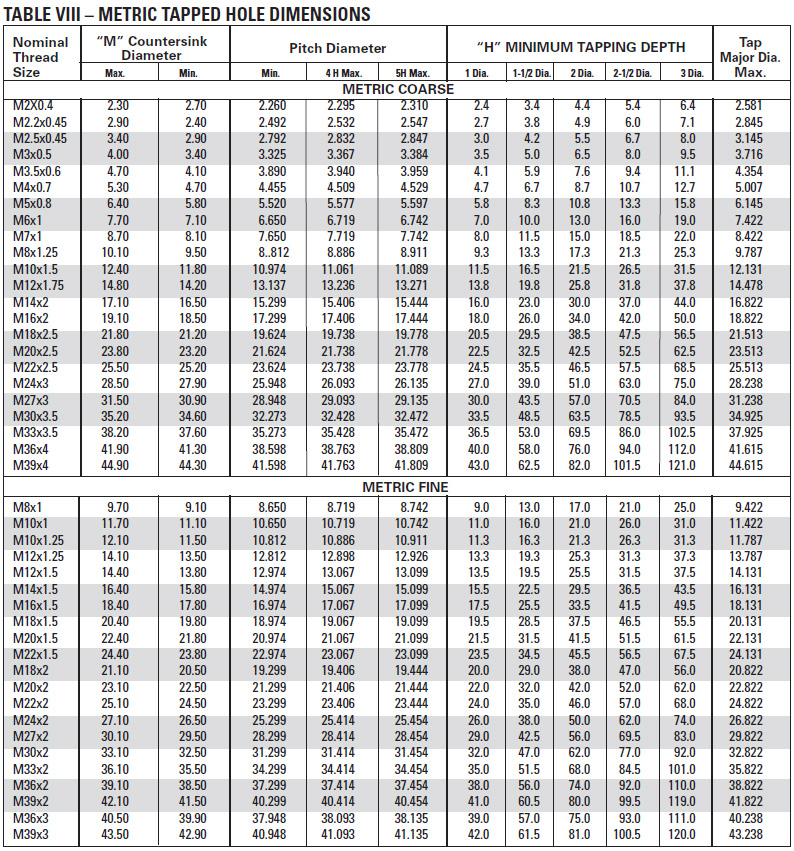

| Heli-Coil taps in various types and

styles produce holes for Tolerance

Classes 4H5H or 3B and 5H or 2B

for use in the general range of

aluminums, magnesiums, mild steels,

free machining stainless steels and

other free machining materials.

Conventional shop practice and

production procedures, speeds,

feeds and lubricants should be

used in combination with proper

fixturing and good tapping machines

or tapping heads. The tapped hole

must be held within the stated pitch

diameter limits for the required

Tolerance Class of fit for the installed

Heli-Coil insert. For Standard (free

running inserts), a tolerance class 5H

or 2B is recommended. For Screw-

Lock inserts, a tolerance class 4H5H

or 3B is recommended in order to

develop higher locking torques. |

|

| helicoil, helicoil insert, helicoil inserts, heli-coil, helicoil tap, helicoil insertion tool, helicoil removal tool, helicoil thread chart, helicoil drill chart, helicoil thread gauge, helicoil kit, helicoil tool kit, helicoil thread repair kit, NASM21209,MS21209 ,NASM33537,MS33537 ,MS122076 to MS124831,NAS1130, LN9039,LN9039A, LN9499 ,LN9499A,DIN8140, MS122076 to MS124831,MA3279 ,MA3280 ,MA3281 ,MA3329 ,MA3330 ,MA3331, SAE8879, BACi12AE,AGS3600, AGS3700, AGS4677, AS6733, AS6734 , AS8455 ,AS8456 ,AS3094 AS3095,AS3096, AS3097, GE N926, N926A ,N926B ,N926C, helicoil tool holder,helicoil tool set ,wire thread insert, self locking insert, screw locking insert |

|

| Download Product Catalogues |

|

|

| |

|

|

| |

|